Wednesday, 2 November 2016

Household Power Saver Woking

Monday, 17 October 2016

Monday, 3 October 2016

Tuesday, 20 September 2016

Induction Cooktop Working

Friday, 2 September 2016

how to run fuse tube light

Thursday, 25 August 2016

DOL Starter controling Diagram

Wednesday, 10 August 2016

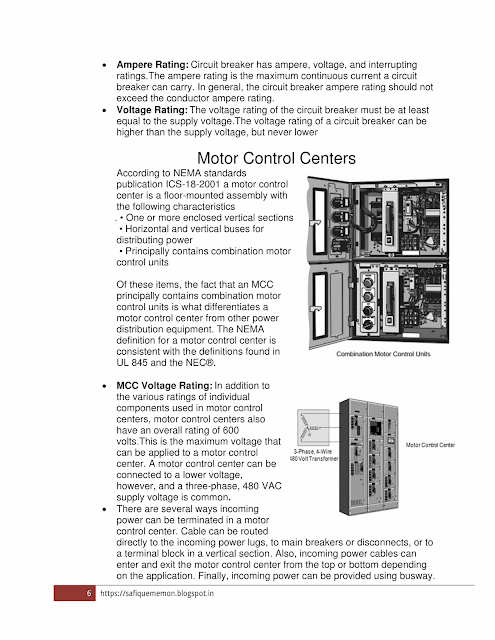

Ferrite Bead

Monday, 8 August 2016

Air Conditioners with Inverter technology

What are the benefits of Inverter Technology?

All air conditioners are designed for high loading. So 1.5ton AC is designed for a specific room size and 1 ton for a different size. But not all rooms are the same size. A standard 1.5ton air conditioner will always operate at high power requirements when the compressor is operating. An air conditioner with inverter technology will work continuously but will only absorb most of the energy needed to maintain the desired temperature. It therefore automatically adjusts its volume according to the requirements of the cooling room. So draw very little power and use smaller power units.

Although airconditioner with Inverter Technology adjusts its volume based on the needs of the room, it is very important to install the right amount of air in the room. Please make sure you check the room and air conditioner capacity before purchase. Keep an eye out for this space as we are in the process of making a comparison of energy saving on different air conditioners.

Are Inverter technology air conditioners slow to cool?

In comparison, inverter tech AC changes the flow rate of the refrigerator based on room temperature. When the temperature is low, the flow rate is low, when the temperature is high, the flow rate is high. And it does not always turn off the compressor. It simply ensures that when the temperature setting is 25, it is maintained at that level.

So the difference is: the non-inverter AC will cool down, while the inverter AC will cool down much better. And thus one may feel that the AC inverter is neither cool nor fast.

The lesser-known benefits of Inverter Technology

Ordinary engines require 3-4 times more current (over current performance) in the beginning. Therefore the size of the inverter / generator required to use any AC or Refrigerator is greatly increased. But Inverter Technology air conditioners and refrigerators with flexible speed engines that start slowly require very little performance at first. Therefore the size of the inverter / generator needed to start is small. For example. A fixed speed of 1.5 ton AC operating at about 10 Amp current may require up to 30 Amp current when starting as well as a 5 kVA inverter / generator. But the inverter technology Air Conditioner requires about 6-7 Amp current and not too much at first and thus a 1.5 kVA or 2 kVA inverter / generator is good enough to support it.

Normal motors have a very low power factor. In commercial and industrial connectivity there is a low power factor charge and a high power factor discount. The inverter technology engine will have a power factor close to the unit (or 1) which not only results in less power consumption but also helps to get discounts on a better power factor.

If you plan to use Solar PV air conditioner, it is best to use inverter technology air conditioner or refrigerator as it not only reduces the size of the PV panel because it consumes less electricity, and reduces the size of the inverter to integrate the PV panel .

Saturday, 16 July 2016

How you can use the 3 phase change over switch in home

For typical domestic use, the device illustrated bellow have two more identical units mounted over a board with some indications regarding the number of phase available and the currently applied change over status.

Similarly the second set of indication lamp is showing the status of the three phases at the outgoing end of the device (Which will be the actual status of the three phases being fed to your home).

whenever there will be an phase outage due to faults or blown fuses at the power distribution feeder end, both sets of same coloured indication lamps will stop glowing to which phase they are assigned for (e.g. if only both sets of Yellow and Blue indication lamps are working that implicates that power supply to Red phase have been disrupted).

And now comes the part where the actual operation of the phase converter/selector will be done. There would be three similar rotary switches with three/four similar markings on it, so lets pick one switch for ease of understanding. Normally, the following would be the positions of the selector switch, for R Phase selection, the knob on switch will be indicating 1 or R. For Y-Phase, the knob will be positioned on 2 or Y and similar for the 3rd of Y phase.

Suppose the Red indication lamps are not working, but other two are working, then the switched have to be adjusted so that only Y and B phase will be supplied further, hence the R-Phase's knob will be rotated and can be placed on either position number 2 or 3 from its earlier position of 1 so that the power line of R phase is connected to that of Y or B-Phase.

So, when the above mechanism is applied, all the 3 indication lamp on the second set will start working although the one indication lamp on the incomer side is still dark, this shows that the changeover have been completed successfully.

Things to remember !!

- Never ever do this change-over operation with your main supply on, in order to avoid a possible flashover, always drop the main MCB of your home before operating the device.

- Never ever use this change over device if you have a direct 3-phase device like flour-mill or water pump of high capacity as the two similar phase will damage the device.

- Always remember to re-position the knobs to its original position once the phase have been restored if the damage caused by heavy flow of current over a single phase have to be avoided.

Thursday, 14 July 2016

Working of tester

- The tester should only be used when you are sure that voltage is within 500 V. Also make sure that proper resistor is connected. Never connect the instrument until you are 100% sure.

- Always use the good quality instrument, you can save a few bucks on low-quality material but it can harm your life.

Tuesday, 12 July 2016

Why don't birds get electrocuted sitting on power lines?

Is it bad to charge your phone over night?

So, is it true? Is charging phone overnight bad?

Well, you’d better ignore that. We couldn’t be more wrong.

And the truth is that Charging phone overnight will not harm your battery in the slightest. Any device with a Lithium Polymer battery must incorporate a charging circuit that will cut off charging power when the battery reaches 100%.

Besides, the smartphone battery is as smart as the phone itself. Apple, Samsung and all the top tech companies, almost of whose products use lithium-based batteries.

Wednesday, 22 June 2016

Magnetic Starter - Control Stations

One of the advantages of magnetic starters is the ability to add control stations. These stations may be located at any convenient location and duplicated as required. The maximum number of stations and their location is unlimited for all practical purposes. Stations are built using Normally Closed (STOP) and Normally Open (START) momentary contact switches. These switches must be rated for the control circuit voltage at a minimum. Over-rated switches will work fine. Many manufacturers incorporate both Normally Open (NO) and Normally Closed (NC) contacts in a single switch body. By rewiring the switch you can change it from one to the other. Many manufacturers also provide interchangeable buttons in at least red and green.

The last station must always be provided to complete the circuit. The intermediate stations may be repeated as many times as required. Suitable 3 conductor control wiring is required from the starter to each of the control stations in turn (daisy chained).

Air Compressor or Float Pump/3ph Starter/1ph Motor

Line Voltage Control Magnetic Starter controlled by a air compressor pressure switch (NC). Includes Auto/Hand/Off control and low oil switch (NC). Both of these are optional and may not be present in all applications. In some cases, the switch will include only Auto/Off. The Auto/Hand/Off is sometimes an integral part of a factory pressure switch. Auto allows for unattended, automatic starting of the compressor when the air pressure in the tank falls below the preset limit. Hand (manual control) allows the pump to be turned on regardless of the position of the pressure switch. This may or may not be appropriate for all applications and is shown in the interest of completeness only. Hand should be used with caution and due consideration to what is happening in the circuit. Off is self explanatory. If no low oil switch is present, merely remove it from the circuit and continue the wires from the start switch back to the coil.

Incidentally, the same circuit can be used to power a sump pump. The float switch (NO) for the sump would be connected in place of the pressure switch. When the switch detects liquid, the contacts will close and the pump motor will start - assuming that the Start Switch is in the Auto position. Hand is obviously desirable in a sump pump application as it allows the pump to be activated even if the float switch is not functioning.

3ph Starter/3ph Motor/Reversible

Line Voltage Control - double contactor three phase motor starter controlling a reversible three phase motor (rev 08 Aug 2006) (Note: L1 becomes T3 and L3 becomes T1 when the reverse relay is actuated.) The motor must be STOPPED before REVERSING unless the contactor allows for on-the-fly reversing. The coils are locked out via the NC contacts (M1, M2) usually contained within the mechanical interlock. When Coil #M1 is engaged, Coil #M2 is locked out and vice-versa.

3ph Starter/1ph Motor

Line Voltage Control three phase (3ph) motor starter controlling a single phase motor (rev 08 Aug 2006) Some 3 phase Magnetic Motor Starters require current to be seen across each of the three overloads. This may be accomplished by directing the output of second circuit back into the input of the third (previously unused) circuit and feeding the motor off of the output of the third circuit (rather than the second). Wiring then becomes: Line 1 → L1 → T1 → Motor 1 (L1-hot 240v or neutral 120v) Line 2 → L2 → T2 → L3 → T3 → Motor 2 (L2-hot 120v or 240v)

Manual Starter? Merely ignore the control wiring in RED

Tuesday, 24 May 2016

Friday, 29 April 2016

Tuesday, 22 March 2016

Sunday, 13 March 2016

BIO-FUELS - BURNING DOMESTIC WASTE

Recently interest has grown in the burning of garbage / domestic waste to produce electricity. This is not a new idea although in the past when waste was burned it created pollution that could even be toxic. Today, the technology exists to remove almost all the pollutants from the fumes produced during the energy production cycle. Special filters remove dangerous chemicals and particles that would normally be found in the fumes.

| ||

1. The domestic waste is sorted usually by hand to remove materials than can be recycled. Steel is removed using electromagnets and this is stored until there is enough quantity for recycling to be economically viable. Aluminium, in the form of cans is removed by hand. Other recyclable materials are collected separately. These include, garden waste, newspapers, cardboard, bottles, waste food and even used batteries.

| ||

2. The waste is then ‘dropped’ into the hopper of a furnace. When the doors slide open it falls into the burning chamber. Gas is normally used to start the fire which burns at a high temperature, destroying the domestic waste.

| ||

Whilst the waste burns it heats a water tank, in turn, producing steam. The steam is used to turn turbines, producing electricity.

| ||

Once steam has been produced, the production of electrical power is no different than that used in any other power station. The high pressure steam is used to turn electrical turbines which produce electricity. The advantage of this way of producing electricity is that the domestic waste that would normally be buried in land fill sites or even dumped far out at sea, is burned. This means that vast areas of land that would have to be used for land fill are free for agriculture or for building.

| ||

The domestic waste is burned in the furnace. This heats water in a tank producing steam. The high pressure steam is used to turn turbines, producing electricity. The steam produced during the process condenses back to water and is recycled for heating once again. Pollutants are removed from the fumes before they are allowed into the atmosphere.

| ||

Saturday, 5 March 2016

Thursday, 18 February 2016

Monday, 1 February 2016

Tuesday, 26 January 2016

Monday, 11 January 2016

tariff

TRANSISTORS

TRANSISTORS A transistor is a semiconductor device that contains three regions separated by two distinct PN junctions. The two junctions are...