TRANSFORMER

MAINTENANCE GUIDELINES

Following specific checking and maintenance guidelines as

well as conducting routine inspections will help ensure the prolonged life and

increased reliability of a transformer. The frequency of periodic checks will

depend on the degree of atmospheric contamination and the type of load applied

to the transformer.

Routine checks and

resultant maintenance

|

Sl

No

|

Inspection

Frequency

|

Items

to be inspected

|

Inspection

Notes

|

Action

required if inspection shows unsatisfactory conditions

|

|

1.1

|

Hourly

|

Ambient Temperature

|

-

|

-

|

|

1.2

|

Hourly

|

Oil & Winding Temperature

|

Check that temperature rise is

reasonable

|

Shutdown the transformer and

investigate if either is persistently higher than normal

|

|

1.3

|

Hourly

|

Load (Amperes) and Voltage

|

Check against rated figures

|

Shutdown the transformer and

investigate if either is persistently higher than normal

|

|

2.1

|

Daily

|

Oil level in transformer

|

Check against transformer oil level

|

If low, top up with dry oil examine

transformer for leaks

|

|

2.2

|

Daily

|

Oil level in bushing

|

|

|

|

2.3

|

Daily

|

Relief diaphragm

|

|

Relief diaphragm

|

|

3.1

|

Quarterly

|

Bushing

|

Examine for cracks and dirt deposits

|

Clean or replace

|

|

3.2

|

Quarterly

|

Oil in transformer

|

Check for dielectric strength &

water content

|

Take suitable action

|

|

3.3

|

Quarterly

|

Cooler fan bearings, motors and

operating mechanisms,

|

Lubricate bearings, check gear boxes,

examine contacts

|

Replace burnt or worn contact or other

parts

|

|

4.1

|

Yearly

|

Oil in transformer

|

Check for acidity and sludge

|

Filter or replace

|

|

4.2

|

Yearly

|

Oil filled bushing

|

Test oil

|

Filter or replace

|

|

4.3

|

Yearly

|

Gasket Joints

|

-

|

Tighten the bolts evenly to avoib

uneven pressure

|

|

4.4

|

Yearly

|

Cable

|

boxes Check for sealing arrangements

for filling holes.

|

Replace gasket, if leaking

|

|

4.5

|

Yearly

|

Surge Diverter and gaps

|

Examine for cracks and dirt deposits

|

Clean or replace

|

|

4.6

|

Yearly

|

Relays, alarms & control circuits

|

Examine relays and alarm contacts,

their operation, fuses etc. Test relays

|

Clean the components and replace

contacts & fuses, if required.

|

|

4.7

|

Yearly

|

Earth resistance

|

|

Take suitable action, if earth

resistance is high

|

IR testing:

The

transformer should be de-energized and electrically isolated with all terminals

of each

winding shorted

together. The windings not being tested should be grounded. The meg-ohmmeter

should be applied

between each winding and ground (high voltage to ground and low voltage to

ground) and

between each set of windings (high voltage to low voltage). The meg-ohm values

along with the

description of the instrument, voltage level, humidity, and temperature should

be

recorded for

future reference.

The

minimum megaohm value for a winding should be 200 times the rated voltage of

the winding

divided by 1000.

For example, a winding rated at 13.2kV would have a minimum acceptable value

of 2640 megaohms

([13,200V x 200] / 1000). If previously recorded readings taken under similar

conditions are

more than 50% higher, the transformer should be thoroughly inspected, with

acceptance tests

performed before reenergizing.

Turns ratio testing:

The

transformer turn ratio is the number of turns in the high voltage winding

divided by the

number of turns in the low

voltage winding. This ratio is also equal to the rated phase voltage of

the high voltage winding being

measured divided by the rated phase voltage of the low voltage

winding being measured.

Transformer turns

ratio measurements are best made with specialized instruments that include

detailed connection and operating

instructions. The measured turns ratio should be within 0.5% of

the calculated turns ratio.

Ratios outside this limit may be the result of winding damage, which has

shorted or opened some winding

turns.

Insulation PF testing:

Insulation PF is the ratio of the

power dissipated in the resistive component of the insulation

system, when tested under an

applied AC voltage, divided by the total AC power dissipated. A

44

perfect insulation would have no

resistive current and the PF would be zero. As insulation PF

increases, the concern for the

integrity of the insulation does also. The PF of insulation systems of

different vintages and manufacturers

of transformers varies over a wide range (from under 1% to

as high as 20%). As such, it's

important that you establish a historic record for each transformer

and use good judgment in

analyzing the data for significant variations.

Acceptance testing

Acceptance tests are

those tests made at the time of installation of the unit or following a service

interruption to demonstrate the

serviceability of the transformer. This testing also applies to drytype

units. The acceptance tests

should include IR testing, insulation PF measurement, and turns

ratio testing, all as described

under periodic tests. In addition, winding resistance measurements

should be made and excitation

current testing done.

Winding resistance measurement:

Accurate measurement of the resistance between

winding terminals can give an indication of

winding damage, which can cause changes to some or all of the winding

conductors. Such

damage might result from a transient winding fault that cleared;

localized overheating that opened

some of the strands of a multi-strand winding conductor; or short

circuiting of some of the winding

conductors.

Sometimes, conductor strands will burn open like a

fuse, decreasing the conductor cross section

and resulting in an increase in resistance. Occasionally, there may be

turn-to-turn shorts causing

a current bypass in part of the winding; this usually results in a

decrease of resistance.

To conduct this test, the transformer is de-energized and disconnected

from all external circuit

connections. A sensitive bridge or micro-ohmmeter capable of measuring

in the micro-ohm range

(for the secondary winding) and up to 20 ohms (for the primary

winding) must be used. These

values may be compared with original test data corrected for temperature

variations between the

factory values and the field measurement or they may be compared with

prior maintenance

measurements. On any single test, the measured values for each phase

on a 3-phase

transformer should be within 5% of the other phases.

Excitation current measurement:

The excitation

current is the amperage drawn by each primary coil, with a voltage applied to

the

input terminals of the primary

and the secondary or output terminals open-circuited. For this test,

the transformer is disconnected

from all external circuit connections. With most transformers, the

reduced voltage applied to the

primary winding coils may be from a single-phase 120V supply.

The voltage should be applied to

each phase in succession, with the applied voltage and current

measured and recorded.

If there is a defect

in the winding, or in the magnetic circuit that is circulating a fault current,

there

will be a noticeable increase in

the excitation current. There is normally a difference between the

excitation current in the primary

coil on the center leg compared to that in the primary coils on the

other legs; thus, it's preferable

to have established benchmark readings for comparison.

Variation in current versus prior

readings should not exceed 5%. On any single test, the current

and voltage readings of the

primary windings for each of the phases should be within 15% of each

other.

Applied voltage testing:

The applied voltage test is more commonly

referred to as the "hi-pot test." This test is performed

by connecting all terminals of

each individual winding together and applying a voltage between

windings as well as from each

winding to ground, in separate tests. Untested windings are

grounded during each application

of voltage.

This test should be

used with caution as it can cause insulation failure. It should be regarded as

a

proof test to be conducted when

there has been an event or pattern in the transformer's operating

history that makes its insulation

integrity suspect.

45

DC applied voltage

tests are often conducted in the field because DC test sets are smaller and

more readily available than AC

applied voltage sets. With DC tests, the leakage current can be

measured and is often taken as a

quantitative measure. However, DC leakage current can vary

considerably from test to test

because of creepage across the complex surfaces between

windings and between windings and

ground.

The use of AC voltage

is preferable since the transformer insulation structures were designed,

constructed, and tested with the

application of AC voltage intended.

Impedance testing:

An

impedance test may be useful in evaluating the condition of transformer

windings, specifically

for detecting

mechanical damage following rough shipment or a service fault on the output

side

that caused high

fault currents to flow through the transformer windings. Mechanical distortion

of

the windings will

cause a change in their impedance. To maximize the effectiveness of this test,

a

measurement should

be taken during the transformer's initial installation to establish a benchmark

value.

An

impedance test is performed by electrically connecting the secondary terminals

together with aconductor capable of carrying at least 10% of the line current

and applying a reduced voltage to

the primary

windings. This is easily accomplished by applying a single-phase voltage to

each

phase in

succession. The applied voltage is measured at the primary terminals and the

current

measured in each

line.

These

values shall be recorded and then calculate the ratio of voltage to current for

each phase.

This ratio should

be within 2% for each phase and should not vary more than 2% between tests.

A variation of

more than 2% indicates the possibility of mechanical distortion of the winding

conductors, which

should be investigated as soon as possible.

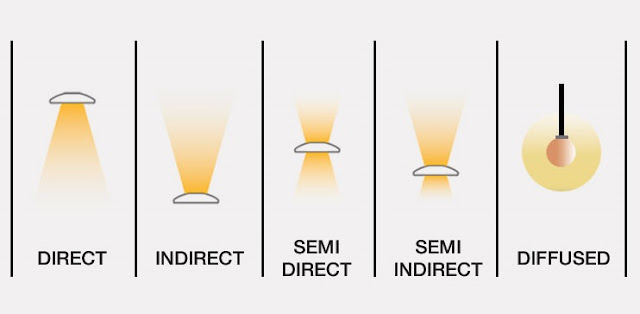

(iii) Semi-direct System

(iii) Semi-direct System

(iv) Semi-indirect Lighting

(iv) Semi-indirect Lighting

(v) General Diffusing System

(v) General Diffusing System