Main Components & Conductor Materials Used in Overhead Lines

Main Components of Overhead Lines

An overhead line may be used to transmit or distribute electric power. The successful operation of an overhead line main Components of Overhead Lines depends to a great extent upon the mechanical design of the line. While constructing an overhead line, it should be ensured that the mechanical strength of the line is such so as to provide against the most probable weather conditions.

An overhead line may be used to transmit or distribute electric power. The successful operation of an overhead line main Components of Overhead Lines depends to a great extent upon the mechanical design of the line. While constructing an overhead line, it should be ensured that the mechanical strength of the line is such so as to provide against the most probable weather conditions.

Conductors :

The lines used for the transmission and distribution of electricity are called conductors. The conductor is mainly used to carry the electrical energy from the generating station to the distribution substation and from the distribution centre to the consumer load centres. Conductors are the most expensive component in the overhead line transmission as the different parameters are taken into consideration for the material selection of the conductor. The size, shape and type of material used are the main factors in selecting conductors.

During the material selection, the current rating and the span of current-carrying factors will play a key role such as they will decide the type of composition that should be used for the conductors. The type of materials used for the conductors are:

a. Copper: The main factor of using copper is that it holds the highest conductivity factor. The most commonly used material for the conductors is copper. There are mainly three kinds of copper such as soft-drawn, medium-drawn and Hard-drawn. The hard drawn copper is used for the construction of the conductors. The main factors for selecting hard drawn copper as it has less elastic factor and more mechanical strength which will make the conductor withstand high current. Due to expensive factors, copper is not directly used for overhead transmission.

b. Aluminium: the most commonly used conductors are made up of aluminium as it is less costly. The weight is also lighter compared to the copper, this advantage makes the pole strength factor decreases. ACSR and AAAC conductors are mainly used for the transmission lines. ACSR is made up of small strands of aluminium twisted together used for the conductors. The twisting of the aluminium strands will give more tensile strength which is used to withstand heavy currents. The main disadvantage of aluminium is it has less conductivity compared to copper and less tensile strength.

c. Galvanized Steel: the major advantage of Galvanized steel is it is cost-effective. It is used for short-distance power transmissions as it consists of some drawbacks such as low conductivity, high resistance and less tensile strength.

d. Cadmium Copper and Copper weld steel are rarely used because of their most expensive factor.

The lines used for the transmission and distribution of electricity are called conductors. The conductor is mainly used to carry the electrical energy from the generating station to the distribution substation and from the distribution centre to the consumer load centres. Conductors are the most expensive component in the overhead line transmission as the different parameters are taken into consideration for the material selection of the conductor. The size, shape and type of material used are the main factors in selecting conductors.

During the material selection, the current rating and the span of current-carrying factors will play a key role such as they will decide the type of composition that should be used for the conductors. The type of materials used for the conductors are:

a. Copper: The main factor of using copper is that it holds the highest conductivity factor. The most commonly used material for the conductors is copper. There are mainly three kinds of copper such as soft-drawn, medium-drawn and Hard-drawn. The hard drawn copper is used for the construction of the conductors. The main factors for selecting hard drawn copper as it has less elastic factor and more mechanical strength which will make the conductor withstand high current. Due to expensive factors, copper is not directly used for overhead transmission.

b. Aluminium: the most commonly used conductors are made up of aluminium as it is less costly. The weight is also lighter compared to the copper, this advantage makes the pole strength factor decreases. ACSR and AAAC conductors are mainly used for the transmission lines. ACSR is made up of small strands of aluminium twisted together used for the conductors. The twisting of the aluminium strands will give more tensile strength which is used to withstand heavy currents. The main disadvantage of aluminium is it has less conductivity compared to copper and less tensile strength.

c. Galvanized Steel: the major advantage of Galvanized steel is it is cost-effective. It is used for short-distance power transmissions as it consists of some drawbacks such as low conductivity, high resistance and less tensile strength.

d. Cadmium Copper and Copper weld steel are rarely used because of their most expensive factor.

Insulators :

Insulators are provided on the supports (poles or towers) to support conductors such that necessary insulation is provided to supports from conductors. This further prevents leakage currents from conductor to earth through supports. Insulators also prevent short-circuiting between conductors and metalwork. The most commonly used insulating materials are porcelain, glass, and Stealite. The various types of insulators are,

Insulators are provided on the supports (poles or towers) to support conductors such that necessary insulation is provided to supports from conductors. This further prevents leakage currents from conductor to earth through supports. Insulators also prevent short-circuiting between conductors and metalwork. The most commonly used insulating materials are porcelain, glass, and Stealite. The various types of insulators are,

Pin-type insulators

Suspension type insulators

Strain insulators

Shackle insulators and

Stay insulators.

Supports :

The function of line supports is to support the conductors and to keep the conductors at a suitable level above the ground. Generally, poles or towers are chosen as supports. These are employed depending upon the working voltage and the regions where they are used. Poles or towers are of various types like,

The function of line supports is to support the conductors and to keep the conductors at a suitable level above the ground. Generally, poles or towers are chosen as supports. These are employed depending upon the working voltage and the regions where they are used. Poles or towers are of various types like,

Wooden poles

Steel poles

RCC poles and

Lattice steel towers.

Cross-arms and Clamps :

These are provided on pole structures to support the insulators and conductors. These are made up of either wood or steel angle sections.

These are provided on pole structures to support the insulators and conductors. These are made up of either wood or steel angle sections.

Guys and Stays :

These are employed to resists the lateral forces at the termination or angle poles by fastening the braces or cables to the poles.

These are employed to resists the lateral forces at the termination or angle poles by fastening the braces or cables to the poles.

Lightning Arrestors :

It is a device used to provide protection against traveling waves or high voltage produce due to lightning by discharging the excessive-high voltage of the line to the ground.

It is a device used to provide protection against traveling waves or high voltage produce due to lightning by discharging the excessive-high voltage of the line to the ground.

Fuses and Isolating Switches :

These are used to isolate different parts of the transmission system.

These are used to isolate different parts of the transmission system.

Earth Wire :

Earth wire is made run on the top of the towers in order to protect the line against lightning.

Earth wire is made run on the top of the towers in order to protect the line against lightning.

Vee-Guards :

To ensure public safety, these are provided below the base overhead line along the street.

To ensure public safety, these are provided below the base overhead line along the street.

Guard Wires :

The guard wires are provided above or below transmission lines while crossing the communication lines and are solidly connected to the earth.

The guard wires are provided above or below transmission lines while crossing the communication lines and are solidly connected to the earth.

Miscellaneous Components :

Phase plates, bird guards, danger plates, barbed wires, vibration-dampers, top hampers, beads for jumpers, etc. The phase plates give information about various phases used, the barbed wire, and are wounded to poles at a height of 2.5 meters in order to prevent the climbing of unauthorized persons. However, danger plates are also provided at a height of 2.5 meters from the ground level.

Phase plates, bird guards, danger plates, barbed wires, vibration-dampers, top hampers, beads for jumpers, etc. The phase plates give information about various phases used, the barbed wire, and are wounded to poles at a height of 2.5 meters in order to prevent the climbing of unauthorized persons. However, danger plates are also provided at a height of 2.5 meters from the ground level.

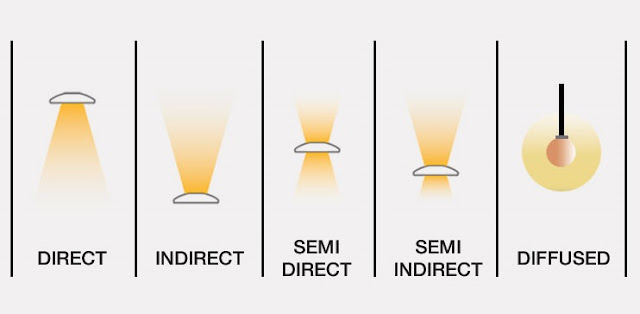

(iii) Semi-direct System

(iii) Semi-direct System

(iv) Semi-indirect Lighting

(iv) Semi-indirect Lighting

(v) General Diffusing System

(v) General Diffusing System