i. Illumination Level:

This is the most vital factor because a sufficient illumination is the basic means whereby we are able to see our surroundings.

For each type of work there is a range of brightness most favourable to output i.e. which causes minimum fatigue and gives maximum output in terms of quality depends upon:

(i) The size of the objects to be seen and its distance from the observer. Greater the distance of the object from observer and smaller the size of the object, greater will be the illumination required for its proper perception and

(ii) Contrast between the object and back-ground-greater the contrast between the colour of the object and its background, greater will be the illumination required to distinguish the object properly. Objects which are seen for longer duration of time required more illumination than those for casual work. Similarly moving objects required more illumination than those for stationary objects.

ii. Uniformity of Illumination:

The human eye adjusts itself automatically to the brightness within the field of vision. If there is a lack of uniformity, pupil or iris of the eye has to adjust more frequently and thus fatigue is caused to the eye and productivity is reduced. It has been found that visual performance is best if the range of brightness within the field of vision is not greater than 3:1, which can be achieved by employing general lighting.

iii. Shadows:

In lighting installations, formation of long and hard shadows causes fatigue of eyes and therefore is considered to be a shortcoming. Complete absence of shadows altogether again does not necessarily mean an ideal condition of lighting instillations. Contrary, perhaps to popular opinion, a certain amount of shadow is desirable in artificial lighting as it helps to give shape to the solid objects and makes them easily recognised.

iv. Glare:

It may be direct or reflected i.e. it may come direct from the light source or it may be reflected brightness such as from a desk top, nickeled machine parts, or calendared paper.

Direct glare from a source of light is more common, and is more often a hindrance to vision. A glance at the sun proves that an extremely bright light source causes acute eye discomfort. Reflected glare is glare which comes to the eyes as glint or reflection of the light source in some polished surface.

v. Mounting Height:

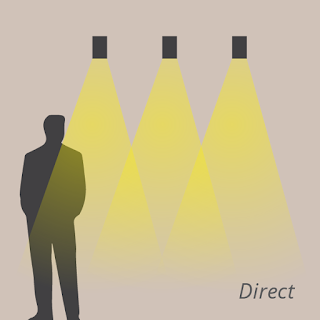

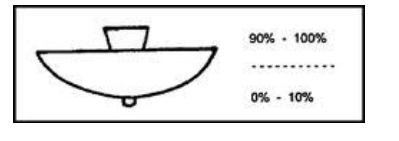

In case of direct lighting it depends upon the type of building and type of lighting scheme employed. For rooms of large floor area, the luminaries should be mounted close to ceiling as possible. In case of indirect and semi-indirect lighting, it would be desirable to suspend luminaries enough down from ceiling to give uniform illumination.

vi. Spacing of Luminaries:

The distance of light source from the wall should be equal to one half the distances between two adjacent light sources. The distance between light fittings should not exceed 1.5 times the mounting height.

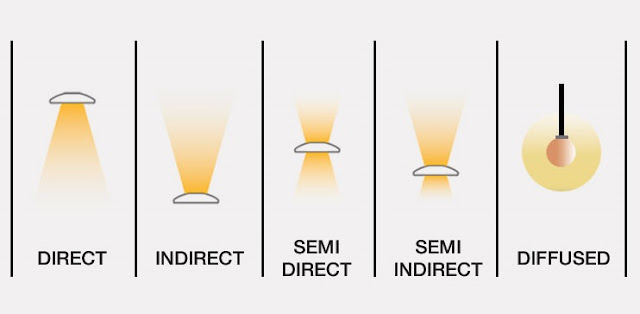

(iii) Semi-direct System

(iii) Semi-direct System

(iv) Semi-indirect Lighting

(iv) Semi-indirect Lighting

(v) General Diffusing System

(v) General Diffusing System