Induction cooktop, uses electromagnetism to turn cooking pans into a furnace (creating heat energy inside the pan itself, instead of shooting it out), which cooks food faster and safer with less energy.

If electricity is supplied to the inlet cooking area, then the current flows into the input coil that generates magnetic energy just above the cooking area. As a magnetic field that flexible magnet is produced as we install AC Current. a powerful electric motor but nowhere to go; we call it eddy current. As it circles inside a metal crystal structure, it exposes its energy. So a metal pan heats up and heats up any food inside it, first by moving (it transfers its heat energy directly to the food) but also by moving.

The induction cooker looks very similar to any other ceramic cooking area, usually with separate areas where you can place pots and pans. The kitchen is usually made of solid, non-heated ceramic glass like Schott CERAN.

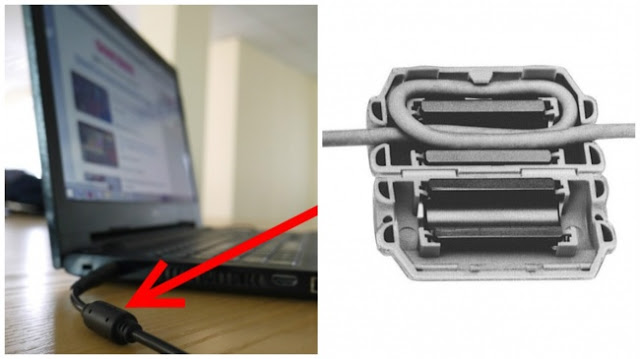

Inside each cooking area, there is a metal coil with a solid wound. When you turn on the power, the switching power flows into the coil and produces an invisible, high frequency, magnetic field alternating around it. Unless there is a pan in the cooking area, no heat is generated: the cooking area remains cold. You may be wondering why we need high frequency. Although your home electricity switch is about 50Hz (50 times per second), the imported cooking area increases this by about 500–1000 times (usually up to 20–40kHz). Since that is more than the distance most of us can hear, it stops any annoying, audible buzzing. More importantly, it prevents the magnetic field from turning the pan into a cooking area.

Place the pan in the cooking area and the magnetic field produced by the coil (shown here with blue stripes) penetrates the metal inside it.

The magnetic field pulls the electric current (eddy) into the pan, turning it into a heater (shown here in orange).

The heat from the pan flows directly into the food or water inside it (by steering).