EHVAC Vs HVDC TRANSMISSION

HVDC vs HVAC Transmission Systems

HVDC stands for High Voltage Direct Current while HVAC

stands for High Voltage Alternating Current. These are typically the rate of

voltage, either DC (HVDC) or AC (HVAC) that are employed for energy

transmission over long distances. HVDC is preferred to be utilized for

transmitting energy over long distances, commonly more than 375 miles.

HVDC vs HVAC Transmission Systems (Reference: tdworld.com)

Nowadays, both formats of power transmission are employed

all over the world. While these both have some advantages and disadvantages, we

will explain each of them briefly in this post below based on different

characteristics to discuss the HVDC vs HVAC transmission systems fundamentally.

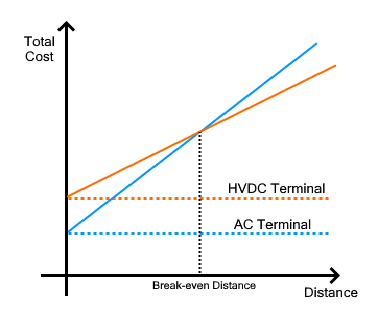

Cost of Transmission

We understand that energy transmission over long-distance

application needs high voltages. The power is used in terminal stations that

modify the voltage rates. So, the total price of transmission is based on the

cost of the transmission line and the terminal source’s situation.

Terminal Station

The great number of voltages transmitted within electrical

terminal sources and their operation are introduced as the voltage conversion.

The system employed for voltage conversion at these sources is mainly

transformers in the case of AC types that is converted between low and high

Voltages. Whereas in the case of DC type, the terminal sources utilize IGBTs or

thyristor-based converters for modification between low and high DC voltage.

Since the transformers are less expensive and more reliable

than these solid-state converters, the AC terminal sources are cheaper than DC

types. Thus, the voltage modification in AC is less costly than DC forms.

Transmission Line

The transmission line price is based on the number of

conductors being employed and the price of the transmission tower.

In the aspect of conductors being employed for transmission

systems, the HVDC transmission type needs just two conductors, while the HVAC

transmission form needs 3 or more than 3 instruments (including the covered

conductor according to the harmful effects).

Because of the massive mechanical load on AC tower systems,

their operation requires to be stronger and it should be taller and wider than

HVDC transmission systems. The transmission line price rises with the distance

and it is far higher than the HVDC line per 60 miles of a transmission path.

Overall Cost of Transmission

The overall cost of transmission is based on the terminal

price (remains fixed) and the line price (rises with distance). As a result,

the overall cost of the transmission system increases with distance.

HVDC vs HVAC Transmission Systems Cost (Reference: electricaltechnology.org)

The transmission path at which the total investment cost for

HVAC begins to increase is introduced as Break-even Distance. This value is

evaluated around 400 – 500 miles. HVDC is a more suitable option for energy

transmission in the break-even distance. Although, below this distance, HVAC is

more effective than HVDC. This data can be simply understood by the previous

diagram.

Flexibility

Because the HVDC transmission is employed for transmission

over long-distance applications between two areas, we cannot extract power at

any section in-between since it would require an expensive converter to reduce

such high DC voltages. In contrast, the HVAC transmission provides flexibility

using a simple and cheap device like transformers at several terminal stations

to control these high voltages.

Power Losses

The HVAC power transmission format has more power wastes

such as Radiation losses, Induction losses, Skin effect, Corona losses, etc.

The radiation & induction losses depend on the magnetic

field variation near the HVAC conductor. A massive conductor starts operating

as an antenna and radiates some power that cannot recover, while the induction

wastes are the energy loss when the current is produced in close conductors

based on the continuously magnetic field variation. Since DC has an identical

magnetic field, the HVDC type is free from these losses.

The alternating current produced in a conductor is separated

in such a method that the current density wants to compose largest at the top

of the conductor and minimum at the middle; this is known as the skin effect.

Because much of the cross-sectional surface is ineffective and we understand

that the resistance is straightly related to the cross-sectional surface, the

resistance value of the conductor rises. The DC in the system is uniformly

spread because the skin effect is just based on the frequency. So, only HVAC

type experience power waste according to the skin effect in this aspect of HVDC

vs HVAC transmission systems.

When the voltage rises more than a specific limit, the air

close to the conductor begins the ionizing process and produces sparks that

lose some power; this is introduced as corona discharge. The losses of corona

discharge are also based on the frequency and because DC systems have zero

frequency, the corona waste in HVAC is almost 3 times higher than that in HVDC.

The Skin Effect in Detail

The skin effect forces the conductor to keep most of the

current at its top and less current at the center. It is based on the frequency

and directly proportional to it. It reduces the efficiency of the conductors

being employed. Thus, in order to provide a larger current, the cross-sectional

section of the conductor requires to be increased.

Skin

Effect in HVDC vs HVAC Transmission Systems (Reference: electricaleasy.com)

So, the HVAC requires a larger diameter device to carry the

equal value of current as compared to the HVDC type employing a shorter diameter

conductor.

Current & Voltage Ratings of Cable

As we discussed before, the current and voltage ratings of a

cable are the optimum allowable range that it can be passed. The AC systems

have a peak current and voltage that is practically 1.4 times greater than its

average (the average practical energy delivered) or its DC norm. But in DC

type, the average and peak values are equal.

Peak

and Average Values for Transmission Systems (Reference: electrical4u.com)

The conductor should be evaluated for the peak voltage and

current for the HVAC type which loses almost 30% of its ideal capacity in

comparison with HVDC form, which uses the complete capacity of the conductor.

So, a conductor with an identical size can be more preferred in HVDC vs HVAC

transmission systems.

Right-of-Way

The right of way is the right method to use the land to and

from another section of land. In the exploration of HVDC type, it includes a

narrower right-of-way since it can employ smaller kinds of towers with fewer

conductors being applied, i.e., two in DC types and 3 in 3-phase AC systems.

Also, the insulators used in the main towers should be rated for peak voltages

in AC systems.

The right-of-way influences the prices of substances used

and fabrication requirements for the different transmission systems. We can

conclude that HVDC types have a narrower right-of-way than HVAC transmission

systems.

Submarine Power Transmission

We use cables in order to move power offshores employing

submarine power transmission. At the same time, the cables provide certain

capacitance generated between two conductors that operate in parallel

arrangement to transmit power over long-distance applications.

The capacitance value is just based on the variation in

voltage which is continuously happening in AC types, and only during switching

mode in DC systems. The cable does not provide energy due to such capacitance

(at the receiving section) before being completely charged. The cable is

discharged and charged continuously in alternating current (50 or 60 times per

second) which forces the system to lose a huge power. In contrast, the cable is

charged only once in DC type. As a result, the submarine power system employed

HVDC for energy transmission.

Controllability of Power Flow

When we discuss the HVDC vs HVAC transmission systems in the

case of controllability, HVDC form uses particular converters of IGBT

semiconductors which can be switched off and on several times in a period and

control the total system, while HVAC has not a controllable part for Power

flow. While the converters used in HVDC are complex, they help in controlling

the distribution of energy to the entire setup and also increase the harmonic

performance. These developed electronic converters provide fast protection

against line errors and fault clearance contrary to the HVAC types.

Circuit Breaker

The Circuit breaker is a highly important section of power

transmission systems. It can cease the whole circuit operation for reaction to

any fault or maintenance. The circuit breaker requires arc-extinguish abilities

in the current to stop the power supply.

The direction and value of the current modify continuously

in HVAC systems and the arc is typically extinguished based on the presence of

several zero currents in a second that present various chances to stop the arc.

Whereas in DC form, the current is fixed and there are no zero currents, so

artificial zero currents should be produced employing particular circuitry to

stop the arc.

As a result, in the comparison of HVDC vs HVAC transmission

systems, the circuit breakers for HVAC are easy to modeling according to the

“self-arc-extinguish” feature. This is while for HVDC, the circuit-breaker

modeling is relatively complex and they are more costly than HVAC types.

Generating Interference

The AC systems produce a magnetic field with continuously

variable values that can cause interference with the conductors in the nearby

communication. Because DC types have a constant magnetic field, they do not

cause such problems.

Key Differences to Contrast Hvdc vs Hvac Transmission

Systems

At what follows, key differences between HVDC vs HVAC

transmission systems are summarized:

- Skin

effect is zero in DC systems. Also, corona wastes are especially lower in

DC type. An HVDC path has noticeably lower wastes in comparison with HVAC

over long-distance applications.

- HVDC

transmission path would cost lower than an HVAC type.

- Based

on the absence of inductance value in DC type, an HVDC path provides

better voltage monitoring. Also, HVDC supplies greater controllability in

comparison with HVAC.

- AC

power grids are normalized for 60 Hz in some regions and 50 Hz in others.

It is impractical to combine two power grids operating at different

frequencies using an AC junction. An HVDC port makes this possible for

power grids.

- Interference

with close relative lines is lower in HVDC types than an HVAC overhead

line.

- The

short circuit current rate in the receiving setup is great in longer

distance HVAC transmission system. An HVDC type does not chip in such

circuit current of the AC form.

Conclusion

In a general comparison for HVDC vs HVAC transmission

systems, HVDC transmission types have many more benefits over HVAC types,

including controllability, stability, etc. HVDC systems are more cost-effective

for distances greater than the break-even point. Submarine HVDC instruments can

be more reliable for use in offshore wind farms as they are less expensive than

undersea HVAC wires. As a result, there is an increasing tendency to choose the

HVDC transmission type. However, HVAC systems are also employed because they

have their particular advantages in distribution and transmission, such as they

can be simply stepped down and stepped up which is an important matter in

certain applications. HVDC is practically a supplement for AC forms rather than

an opponent.