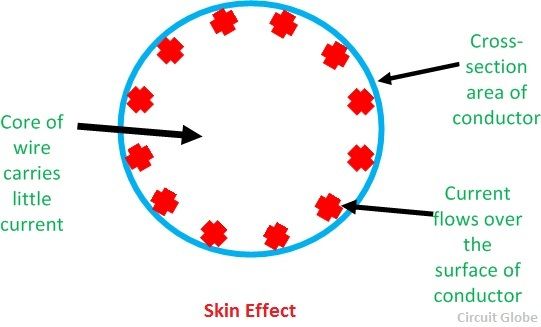

Skin Effect

The non-uniform distribution of electric current over the surface or skin of the conductor carrying a.c is called the skin effect. In other words, the concentration of charge is more near the surface as compared to the core of the conductor. The ohmic resistance of the conductor is increased due to the concentration of current on the surface of the conductor.

Skin effect increases with the increase in frequency. At low frequency, such as 50Hz, there is a small increase in the current density near the surface of the conductor; but, at high frequencies, such as radio frequency, practically the whole of the currents flows on the surface of the conductor. If d.c current (frequency=0) is passed in a conductor, the current is uniformly distributed over the cross-section of the conductors.

Why skin effect occurs?

Let us consider the conductor is made up of a number of concentric cylinders. When a.c is passed in a conductor, the magnetic flux induces in it. The magnetic flux linking a cylindrical element near the center is greater than that linking another cylindrical element near the surface of the conductor. This is due to the fact that the center cylindrical element is surrounded by both the internal as well as the external flux, while the external cylindrical element is surrounded by the external flux only.

The self-inductance in the inner cylindrical element is more and, therefore, will offer a greater inductive reactance than the outer cylindrical element. This difference in the inductive reactance gives a tendency to the current to concentrate towards the surface or skin of the conductor.

The current density is maximum at the surface of the conductor and minimum at the center of the conductor. The effect is equivalent to a reduction of the cross-section area of the conductor and, therefore the effective resistance of the conductor is increased.

Factors affecting skin effect

- Frequency – Skin effect increases with the increase in frequency.

- Diameter – It increases with the increase in diameter of the conductor.

- The shape of the conductor – Skin effect is more in the solid conductor and less in the stranded conductor because the surface area of the solid conductor is more.

- Type of material – Skin effect increase with the increase in the permeability of the material (Permeability is the ability of material to support the formation of the magnetic field).

Points-to-remember

- The Skin effect is negligible if the frequency is less than the 50Hz and the diameter of the conductor is less than the 1cm.

- In the stranded conductors like ACSR (Aluminium Conductor Steel Reinforced) the current flows mostly in the outer layer made of aluminum, while the steel near the center carries no current and gives high tensile strength to the conductor. The concentration of current near the surface enabled the use of ACSR conductor.

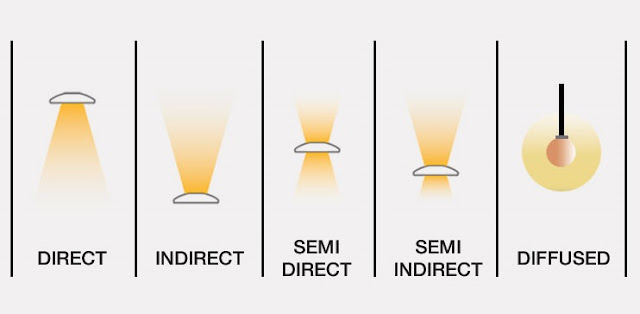

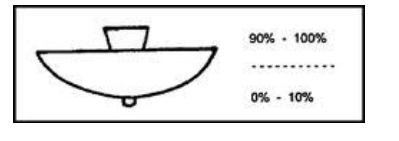

(iii) Semi-direct System

(iii) Semi-direct System

(iv) Semi-indirect Lighting

(iv) Semi-indirect Lighting

(v) General Diffusing System

(v) General Diffusing System